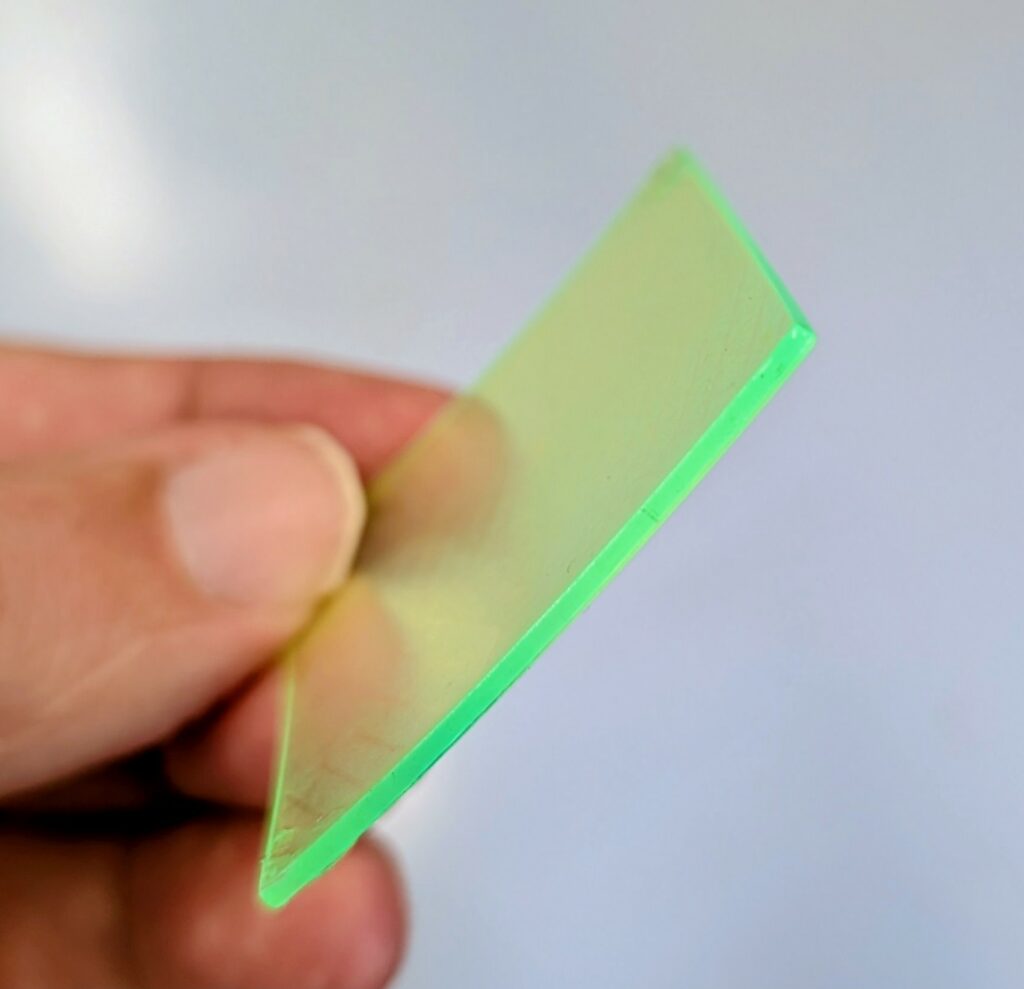

We design optical plastic parts:

With special dyes inserted in liquid phase into the monomers: fluorescent or scintillating agents. We strive to make the manufacturing process simple and suitable for small and medium-sized production runs. Parts intended for scientific research or targeting systems (sights).

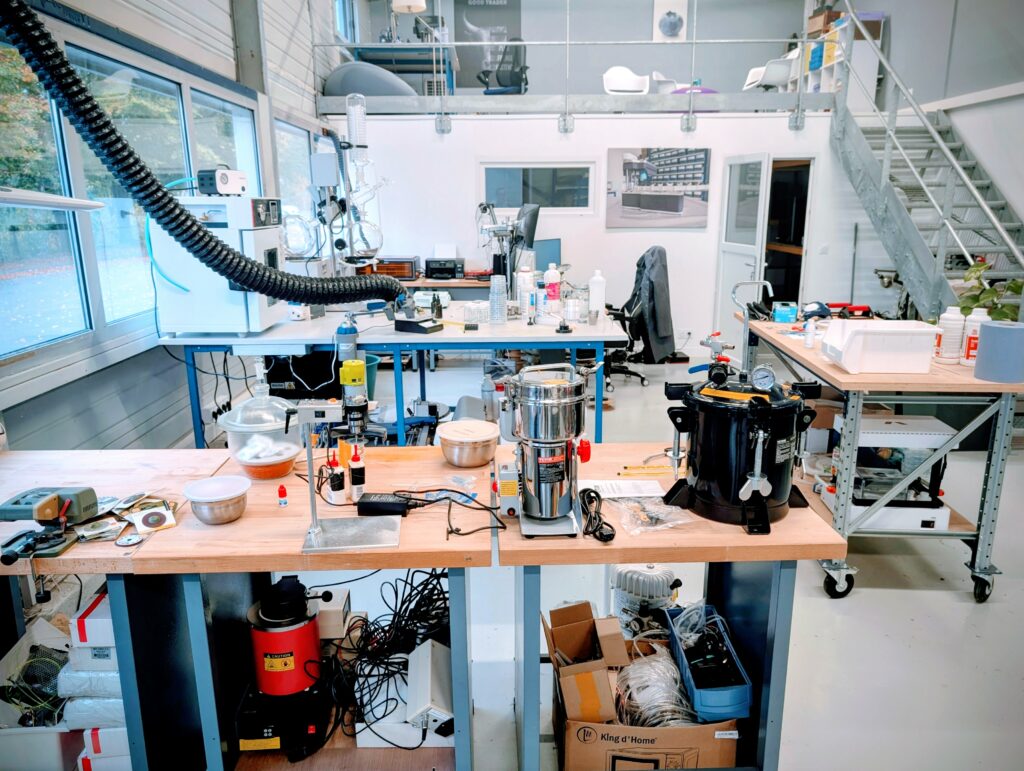

Once combined with special fillers, the monomers are polymerized in several ways: Hot, under vacuum or pressure, cold, or UV, and 3D printing of transparent filled resins

The materials used are: Polystyrene, Acrylic, PMMA, epoxy, PTFE, PET, ABS, Polyesters and fluorinated plastics

Only premium resins with high optical transparency and adjusted refractive indices

More info : lak@northcopter.com

Northcopter is part of Northcopter Agrosta – Our sister activity is a wellknown inventor and manufacturer of scientific instruments and colorimeters. Our company is based in France, has an equity capital of more than 1 million euros, and is fully dedicated to innovation and research

Laurent Klotz, our founder, is a specialist of polymers since 25 years, For 10 years, he owned Europe’s last fluorescent optical fiber manufacturing workshop, which originated from a laboratory belonging to the French Atomic Energy Commission.